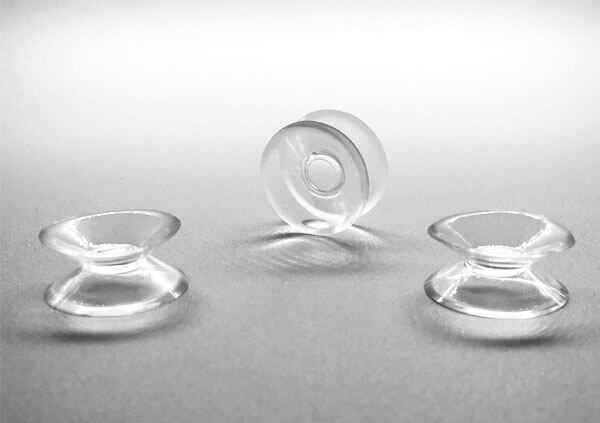

professional Suction Cups manufacturer

We are a professional suction cups manufacturer with over 20 years experience. Design and manufacture more than 5000 kinds of suction cups for customer. We use the automatic vulcanizing machine and raw material extraction equipment to ensure the high product quality. Variety problems from design to production can be solved due to our rich experience.

Why choose us

Offer Cusotm service

Only need to provide the samples or drawing, we can manufacture it strictly according to your need. The minimum tolerance is ±0.05mm.

High quality

ISO9001 certificated and meet the RoHS and Reach standard. We never use the reclaimed materials.

Professional skills

We are a professional suction cups manufacturer with over 20 years experience. Variety problems from design to production can be solved, and we offer the best Technical After-sale service. So that we can make sure the products will meet your need.

Efficiency

We have a full set of production lines, from drawing design to mold manufacturing, material formulation and mass production, all processes are completed made in our own factory. Since there is no outsourcing process, we can speed up the progress, and complete all the processes within 48 hours at the earliest, and deliver qualified goods to you.

Free Samples

Worry about the quality? Contact us for FREE samples! You only need to pay the freight and we will send it to you immediately!

Any questions? Contact us for more information!

OUR Servers

Free Design

Our engineers can offer custom service for making the perfect Products. All you need is tell us your ideas.

Free Samples

After the mold is completed, we will provide you with free samples for testing.

High Quality Mass Production

RoHS and Reach standard certificated.ISO9001 quality management system meet to control the quality.

How Does a Suction Cup Work?

What is it?

A products that can use the difference between the internal and external atmospheric pressure and adsorbed on the object, or a tool that can grab the object. If you need to hang something on the glass, you can use the window suction cups.If you need to pick up a glass or anything that has a smooth, non-porous surface, you can use glass suction cups. They are usually in round shape, but some are rectangular. Most importantly, they are made of airtight materials.

How they Work

The airtightness of material between Rubber and silicone suction cups are both good. The bottom of caps has a concave down area. When we use it, we need to force to press the sucker on the flat and smooth surface. So that it can remove the internal air. Once squeeze the air out, it will turn into vacuum. As the atmospheric pressure are always trying to keep its equilibrium, this pressure push the external air. Since it cannot penetrate the surface of the sucker, it forces it to hold the sucker firmly to the surface.If the suction cup surface or edge is damaged and external air enters the suction cup, the suction cup will not work properly and will fall off.

It is very important to check the airtightness before using the suction cups.Especially the industrial suction cups and heavy duty suction cup hooks.It is also necessary to confirm whether the weight of the adsorbed objects exceeds the adsorption capacity(safety factor must be ≥2). As they are big suction cups, the mounted or adsorbed objects are very large or bulky. Once the suction cup falls off, serious consequences will be caused.

Sucker application scenario

They have a wide range of applications in life and industry.

- In a bathroom or kitchen, using suction cup hooks to hang some objects onto the glass or tiles surfaces.

- Using the suction cup with screw on the bottom of mechanical equipment or household appliances. Use as a suction cup feet to fix the object position and prevent sliding.

- In industrial production, the manipulator use small suction cups to grab objects.

- A double sided suction cup can be used for two pieces of glass by placing it between two glass, cups can support and secure with it.

- Using powerful suction cups to climb glass walls of high-rise buildings

- Using suction cup pads on your car to place your phone

- Using roof rack suction cups in the top of car for luggage or bikes

Physical Properties Of Suction Cups

| Material Name | Tmperature Range | Rebound Resilience | Tensile Stregth | Wear Resistance | Oil Resistance | Weather & Ozone Resistance |

|---|---|---|---|---|---|---|

| Natural Rubber | -70 to 80 ℃ (-96 to 170℉) | Excellent | Excellent | Excellent | Poor | Very Good |

| NBR | -35 to 130℃ (-31 to 266℉) | Very Good | Very Good | Very Good | Excellent | Very Good |

| HNBR | -35 to 160℃ (-31 to 320℉) | Excellent | Excellent | Excellent | Excellent | Excellent |

| SILICONE | -75 to 280℃ (-103 to 536℉) | Very Good | Good | Good | Good | Excellent |

| Polyurethane | -20 to 80℃ (-25 to 176℉) | Excellent | Excellent | Excellent | Excellent | Good |

| VITON | -25 to 300℃ (-13 to 572℉) | Good | Good | Excellent | Excellent | Excellent |

Suction Cup Materials List

Natural Rubber

Natural Rubber suction cups has a High tensile strength and tear strength, strong and not easy to crack, it also has good insulation performance

NBR

For oil contact suction cups, the NBR material are the best. NBR is a semiconductor rubber material with relatively low volume resistance and antistatic properties.

HNBR

HNBR is high saturated elastomer, which obtained by special hydrogenation of nitrile butadiene rubber, with high temperature resistance of 130 ~ 180℃, cold resistance of -55 ~ -38℃, excellent mechanical performance, high strength, high tear resistance, excellent abrasion resistance, etc. It is one of the rubber with excellent comprehensive performance.

SILICONE

Silicone suction cup is bright in color, safe and environmentally friendly, and can be directly contact with food and skin. They are very resistant to aging, have no rejection reaction with animals, and have good anticoagulation ability, which is especially suitable for medical products.

Polyurethane,

Compared with other rubber, Polyurethane has higher flexibility, resilience, mechanical strength and oxidation stability, etc. Excellent oil, water and fire resistance.Polyurethane are very widely used.

VITON

VITON suction cup has high chemical stability which are a best material for strong acid and alkali environment. It has excellent high temperature resistance and can even work for a long time at 300℃.

What sizes a suction cup do you need?

Suction of Suction cups: The force that separate the sucker from the surface of the adsorbing object.

Calculation Method:

F:The suction(KG)

S:The surface area that sucker covered(c㎡)

P:The outer pressure of sucker. Generally means the Atmospheric Pressure.

For example, If a diameter of sucker is 100 mm(10 cm),and the surface area that sucker can covered is 78.5 c㎡. So, in theory, the biggest suction force will be 78.5 KG. But as the vacuum degree cannot never reach 100%,generally it will be counted as 70%, then the suction should be: F=78.5*0.7=54.95 KG. Also, according to the international standard, the safety factor of suction cups should be ≥2, so the suction should also divide this safety degree.

All in all, a 100 mm diameter suction cups should hold a weight ≤27.47 KG.

This calculation method should meet the following conditions:

1. The diameter will not changed when pull the cups.

2. The seal of cups are good, and no air release from the gap

3. The cups will not slide or fall off when it adsorb vertically.